Long-term benefits from Lean Study Mission to Japan

Leila Henderson | inBusiness South Australia | 1 February 2014

Japan has been a beacon for success in manufacturing for over half a century, yet it has faced challenges that would have crippled another nation – a market downturn caused by the global financial crisis, the 2011 triple disaster, and a drop in exports to China, and the high value of the yen to name a few.

Now South Australian companies have learned first-hand how Japanese businesses implemented productivity improvements and developed strong management foundationsover recent decades that allowed them to weather the storm and remain competitive on the global stage.

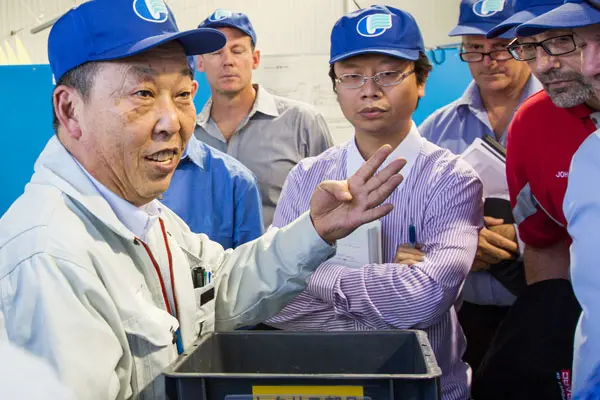

The Australian Industry Group Lean Study Mission to Japan, led by Wayville-based lean manufacturing consulting firm Shinka Management, has provided businesses like Redarc Electronics and Coopers with invaluable insights and first-hand experience of Lean best practice.

Tour leaders Paul Smith and Ben Sparrow of Shinka Management organised, facilitated and interpreted during the 2013 tour.

Paul Smith said that the idea for the lean study mission to Japan, which has been run annually since 2007 as the Shinka Management Lean Japan Tour, originated from awareness that in Australia there had “not been a genuine example of lean manufacturing being applied over an extended period of time.

“A major objective of the tour was to provide opportunities for senior management from Australian industry to visit Japanese companies that excel in lean manufacturing, and to find out how, while they have experienced similar challenges to Australia relating to cost of labour and strong currency, they remain competitive.”

Innes Willox, Chief Executive of the Australian Industry Group, views opportunities such as the tour as important to developingindustry competitiveness.

“With the ongoing competitive pressures on local manufacturing and especially the recent events affecting manufacturing in Australia, the need to strengthen our productivity improvement capability is more apparent than ever. The Australian Industry Group Lean Japan Tour is timely in providing the opportunity to learn from the decades of lean management innovation and know-how that has been developed in Japan.”

Japan has been a beacon for success in manufacturing for over half a century, yet it has faced challenges that would have crippled another nation – a market downturn caused by the global financial crisis, the 2011 triple disaster, and a drop in exports to China, and the high value of the yen to name a few.

Japan has been a beacon for success in manufacturing for over half a century, yet it has faced challenges that would have crippled another nation – a market downturn caused by the global financial crisis, the 2011 triple disaster, and a drop in exports to China, and the high value of the yen to name a few.

Now South Australian companies have learned first-hand how Japanese businesses implemented productivity improvements and developed strong management foundationsover recent decades that allowed them to weather the storm and remain competitive on the global stage.

The Australian Industry Group Lean Japan Tour, led by Wayville-based lean manufacturing consulting firm Shinka Management, has provided businesses like Redarc Electronics and Coopers with invaluable insights and first-hand experience of Lean best practice.

Tour leaders Paul Smith and Ben Sparrow of Shinka Management organised, facilitated and interpreted during the 2013 tour.

Paul Smith said that the idea for the lean study mission to Japan, which has been run annually since 2007, originated from awareness that in Australia there had “not been a genuine example of lean manufacturing being applied over an extended period of time.

“A major objective of the tour was to provide opportunities for senior management from Australian industry to visit Japanese companies that excel in lean manufacturing, and to find out how, while they have experienced similar challenges to Australia relating to cost of labour and strong currency, they remain competitive.”

Innes Willox, Chief Executive of the Australian Industry Group, views opportunities such as the tour as important to developingindustry competitiveness.

“With the ongoing competitive pressures on local manufacturing and especially the recent events affecting manufacturing in Australia, the need to strengthen our productivity improvement capability is more apparent than ever,” said Innes.“The Lean Japan Tour is timely in providing the opportunity to learn from the decades of lean management innovation and know-how that has been developed in Japan.”

The 15 participants on the 2013 lean study mission came from a broad range of industries, including automotive, manufacturing, food and beverage, transport, government, and software development.

“The participants discussed with Japanese management how to establish, implement and sustain lean programs, and they brought this knowledge back to Australia for the betterment of their organisations and the industry as a whole,” Paul said.

“In most cases, these factories are decades ahead of Australian factories, yet management from the host companies were very open in discussing both successes and failures along their journeys.”

Shinka Management planned last year’s lean study mission to Japan to include host companies in several different industries ranging from large corporations right down to organisations that employ fewer than 50 people.

“This was noted by participants as useful to see how improvement programs differ depending on scale and type of organisation, yet still have a common foundation and concepts,” Paul said.

In addition to looking at companies that had implemented lean over several decades, the tour included a visit to a company that had only recently set out on its lean journey.

“Managers shared with us their learnings on how to implement cultural change in their workforce and achieve significant tangible results from lean implementation that saved them from bankruptcy following the GFC,” Paul said.

Jeremy Hawkes, Managing Director of Bowhill Engineering, attended the Lean Japan Tour as part of his Industry Leaders Fund scholarship.

He said he chose to join the tour because Bowhill Engineering had just begun its lean journey.

“With eight of our staff beginning a Certificate IV in Competitive Manufacturing, I felt it was important to witness first-hand what a world-class productive and efficient manufacturing environment looks and feels like,” Jeremy said.

The group had several exclusive opportunities to visit companies such as Rinnai and Chuo Malleable Iron that generally do not accept groups into their factories. They also spent two days at a Toyota Group lean training facility, only made possible through the close relationship Shinka Management has Japanese Industry.

Geoff Vogt, CEO of the Industry Leaders Fund, said that Jeremy’s attendance would result in a “significant multiplier benefit to the local community” as he shares his knowledge with his deep networks around the Murraylands.”

Japan Lean Tour alumnus Gilbert Bruton, TPM Co-ordinator for Coopers Brewery Ltd, said the tour would benefit any company with a desire to forge change, but warns, “…this could lead to some serious self-analysis on how GOOD companies operate!”

Andrew Marshall, Production Manager of Wineworks Marlborough in New Zealand, admired the Japanese systems, machinery, processes and people.

“The passion for lean manufacturing shown by every staff member was evident and the dedication shown at all levels of management was significant,” Andrew said. “The lean implementation is at such a high level at some of the sites that you realise how many more opportunities there are at your own site.”

“Even where the factories are unrelated to your own industry, the message is more about the process and disciplines used to get the business to the current state. Small steps to achieve the ultimate goal.”

Jeremy Hawkes said that the perspectives and principles he learned in Japan would extend to everything he does, “how you react when things go wrong and how important it is to continuously improve in everything that you do.”

“It’s hard to know what is out there beyond the boundaries of SA and Australia, but it is so important that we do know!”

Lean Study Mission to Japan

The Shinka Management Lean Japan Tour, has taken place every year since 2007. In 2014 two lean study missions will be held in Japan from 18-24 May and 9-15 November.

“A key difference for 2014 is that we are looking to add a couple of food and beverage companies into the itinerary,” said Paul Smith.

The lean study mission also includes cultural activities and a seminar on Japanese business etiquette and doing business with the Japanese.