Case Study – The Lean Transformation of Escorial

How Escorial Improved Productivity While Empowering Its Workforce and Building a Culture of Continuous Improvement.

This case study explores the lean transformation of Escorial, highlighting the challenges faced, strategies employed, and remarkable outcomes achieved through a lean implementation program. It serves as a testament to the power of lean principles in revitalizing operational performance and driving sustainable success in a competitive industry.

Introduction

Escorial, a renowned Argentine manufacturer in the white goods industry, has been a household name for decades. Specializing in the production of stoves, water heaters, and home heating solutions, Escorial prides itself on delivering high-quality, durable, and energy-efficient products to consumers across Argentina and beyond. However, the company faced challenges in maintaining competitiveness amidst a volatile economic environment, rising operational costs, and increasing demands for volume, customization, and quality from its customers.

Recognizing the need for a transformative approach to address inefficiencies and sustain long-term growth, Escorial partnered with Shinka Management. Backed by global experience in applying Japanese lean manufacturing techniques, Shinka Management developed a lean transformation project that commenced with a one-week lean training program in Japan for key personnel. This was followed by an onsite lean transformation initiative at Escorial’s two plants – Suipacha and 25 de Mayo – in Buenos Aires Province. This case study covers the activities and results from July 2023 to December 2024.

The project was led by Daniel Andreu, a senior consultant at Shinka Management with extensive experience in implementing lean transformation programs in Latin American manufacturing industries. Daniel’s deep understanding of the local business context and his expertise in the Toyota Production System (TPS) made him an ideal partner for Escorial on this journey.

The Specific Needs

Escorial identified several critical needs that formed the foundation of its collaboration with Shinka Management. Alongside safety, which is always a priority, these needs were deeply rooted in the company’s current challenges and its aspirations for sustainable success:

Enhanced Operational Efficiency

Escorial’s production processes were hindered by inefficiencies such as overproduction, excess inventory, and long lead times. A systematic approach was required to eliminate waste, optimize workflows, and increase productivity.

Improved Product Quality

With growing customer expectations for durable, high-performing, and energy-efficient appliances, Escorial faced pressure to reduce defects and improve process consistency.

Workforce Capability Development

Escorial recognized that sustainable lean transformation relies on its people. The development of technical, managerial, and leadership skills needed to be mapped, understood, and acted upon.

Sustainability

The team agreed that long-term success would depend on leadership behavior and cultural alignment. Leadership practices needed to evolve, and a generational transition had to be managed to ensure future leaders would embrace lean principles.

By addressing these specific needs, Shinka Management laid the groundwork for a transformative lean journey that would not only improve operational performance but also position the company for long-term resilience and success.

Having identified these needs, and under Daniel’s guidance, Escorial’s top management understood that a comprehensive and systemic approach was essential. Implementing isolated lean tools would not suffice.

- Alignment – Level up lean concepts and define goals.

- Understanding – Visualize and grasp the current status.

- Improvement – Identify and address improvement opportunities.

- Sustain – Maintain progress, correct mistakes, and shape the future.

Daniel recommended using the SMW’s lean maturity assessment as a starting point.

Baseline

With Escorial’s needs clarified, the next step was establishing a baseline. While it might be tempting to quantify progress solely through productivity metrics, doing so could overlook the cultural and human aspects of the transformation.

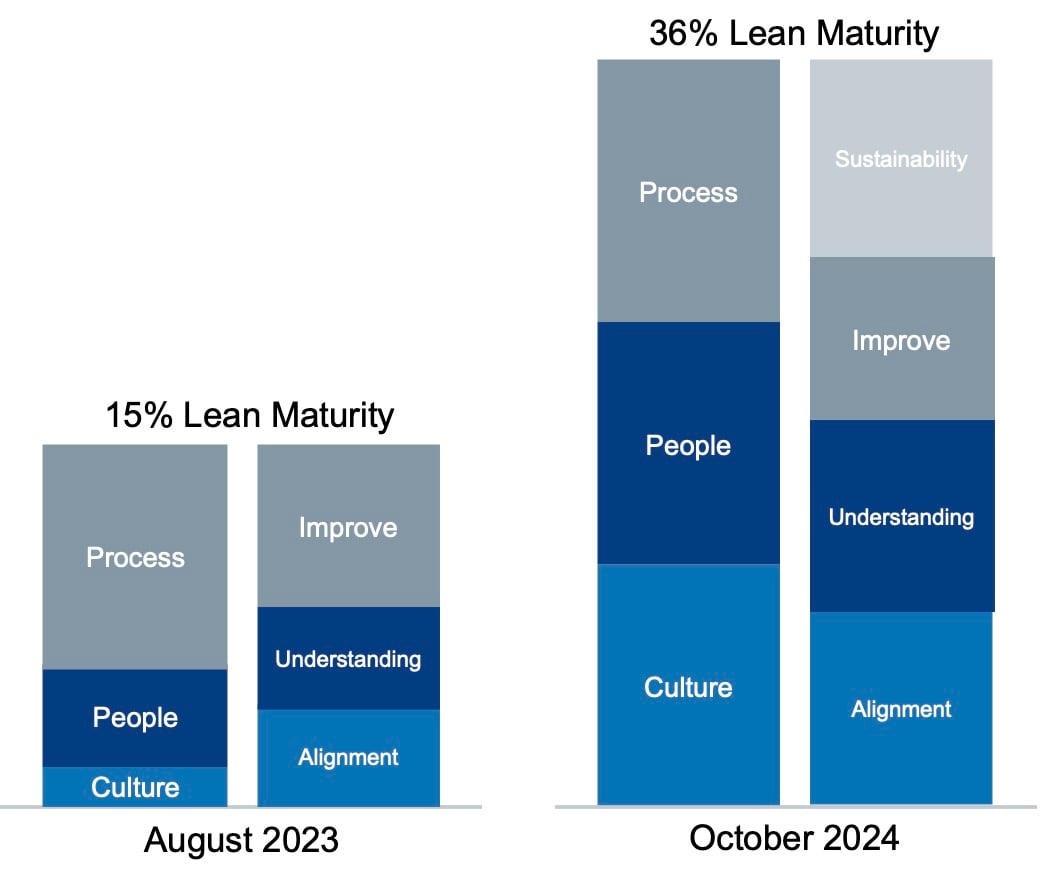

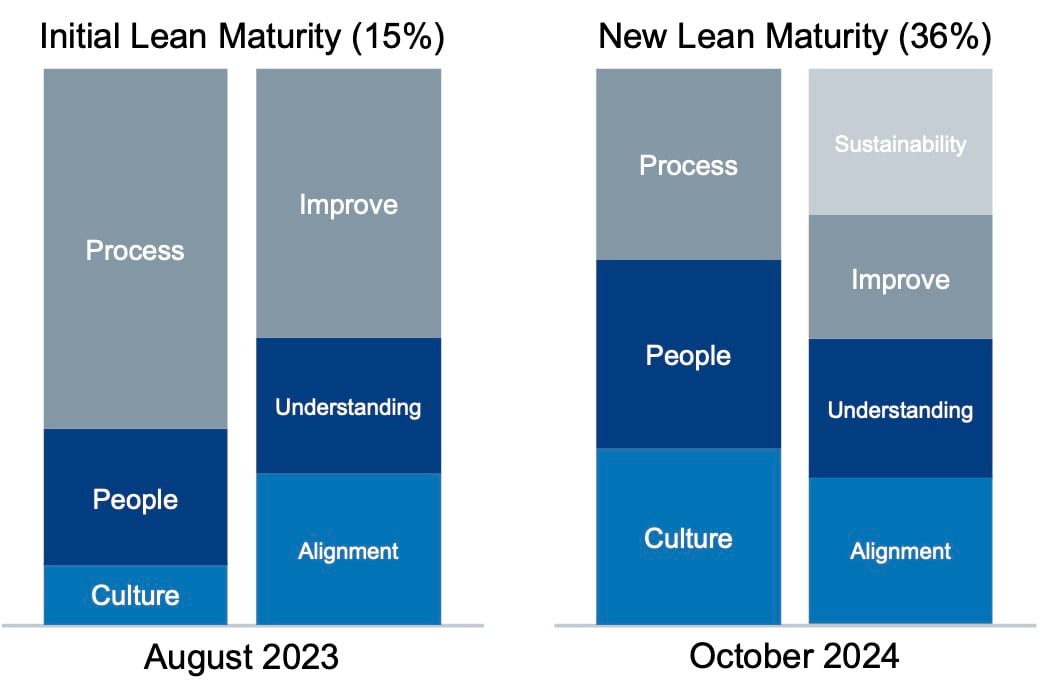

Shinka Management’s senior consultant conducted a lean maturity assessment across both sites. This tool evaluated not only the use of lean tools but also routines and leadership behaviors critical to developing and maintaining a kaizen culture.

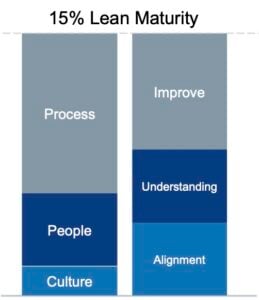

The assessment reviewed each lean concept across three dimensions – Processes, People, and Culture – by rating the maturity of technical elements and appropriate leadership behaviors.

Initial Assessment: Low lean maturity. Little effort on Culture and no effort on Sustainability.

For example, under the “Understanding” stage within the “Processes” dimension, the concept of Genba Walks includes:

- Technical Element: “Work teams know and can identify the 8 wastes.”

- Leadership Behavior: “Leaders systematically go to the shop floor to verify abnormalities.”

Initial Assessment Results:

- 25 de Mayo: 15% lean maturity

- Suipacha: 19% lean maturity

- Culture dimension: 4% at both plants

The results showed most of Escorial’s efforts were focused on tools within the “Improvement” stage, with minimal activity in “Alignment” and “Understanding,” and none in “Sustainability.” This confirmed management’s concern that previous lean efforts were fragmented, demotivating, and unsustainable.

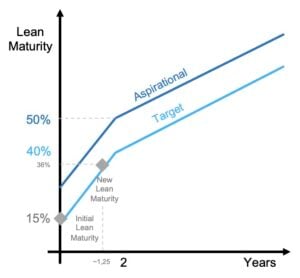

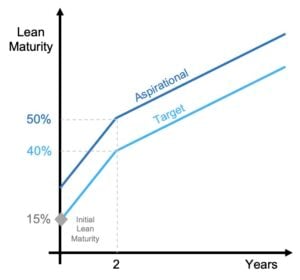

Lean Transformation Goals

The primary goal of the lean transformation project at Escorial was to increase Escorial’s lean maturity, thereby enhancing its continuous improvement culture. This would be pursued through the creation and rollout of the Escorial Production System, grounded in the Shinka Management Way.

By advancing lean maturity, Escorial aimed not only to improve operations but also to foster an empowered workforce and develop leadership aligned with lean values. The focus on people and leadership development would drive productivity, quality, and resilience.

Targets for the 18-month project:

- Expected: 40% lean maturity at each plant

- Aspirational: >50% lean maturity

Daniel played a key role in helping leadership define and communicate these goals using Hoshin Kanri, a strategic planning method for aligning company-wide objectives and cascading goals throughout the organization. Every employee came to understand their role in achieving these goals, creating a unified effort towards improving lean maturity and embedding a culture of continuous improvement into Escorial’s DNA.

The Lean Transformation Team

Lean transformations require a dedicated internal team to lead the journey. This approach ensures that expertise remains within the organization and helps reduce resistance, as the change is driven by colleagues rather than external parties.

Escorial’s top management demonstrated full commitment by forming a dedicated deployment team. In addition, implementation leaders were appointed across departments, and the Industrial Director was named project sponsor—reinforcing organizational alignment and boosting morale.

Training

Alignment in understanding among deployment team members is essential when spreading a methodology inside an organization. Daniel designed a training program to cover both technical and leadership aspects, preparing the team to lead the lean transformation.

The internal deployment team received 30 hours of training on lean leadership and implementation concepts, covering topics such as:

- Lean principles

- Kaizen

- Role of senior management

People development

- 5S

- Visual management

- Standard work

Additionally, Daniel coached the team on feedback and strategies to support behavioral change.

Following this, the team trained 550 associates across the two plants within six months – a testament to the successful transfer of knowledge and ownership.

The “Little House”

After the initial round of training with Escorial’s top management and the deployment team, the team was ready to start developing Escorial’s own production system. This was an exciting time for Escorial, with motivation and staff buy-in increasing every day. Escorial’s leadership knew that they had an opportunity to create a unique way to operate as an organization that would allow them to thrive whilst fostering a culture of continuous improvement and developing people.

Many lean management frameworks, despite their unique branding and adaptations, tend to converge on a familiar structure reminiscent of the Toyota Production System. Often, referred to as the “little house,” these frameworks universally place quality, customer satisfaction and people development or some combination of these, as structural parts of a house. Rather than initially adopting this traditional house metaphor, the team drew inspiration from something closer to home—the kitchen.

- Base: Safety, stability, and movement (sustained improvement)

- Oven: People – the heart of the organization

- Dials: Quality control – fine adjustment to get the recipe just right

- Stovetop: Energy and value creation for customers

Eventually, however, the metaphor was adapted back into the more conventional house structure due to its clarity and recognizability. This creative process significantly increased team ownership and engagement.

Together with the framework of the production system, Escorial’s top management established the purpose of the Escorial Production System, aligned with their mission and vision.

Purpose:

To achieve customer satisfaction by developing people and minimizing waste through standardized, robust processes within a culture of continuous improvement.

Mission:

Challenge ourselves every day to provide the best solutions to our customers.

Vision:

To be the most recognized appliance company in Argentina.

Communication

Escorial’s leadership recognized early on that a production system sitting on a shelf would accomplish nothing. They actively communicated the new direction across the company, supported by the implementation team.

The messaging focused on:

- Humility and collaboration

- Development of people and workplace culture

- Shinka Management’s role as coach and guide

This approach built trust and a shared sense of purpose.

KPI Tree

The time came for establishing clear objectives that reflected the company’s vision and priorities, ensuring that safety, quality, productivity, and lean maturity were fundamental pillars.

While Hoshin Kanri is traditionally used in lean transformations in order to define and cascade KPIs, Escorial was already utilizing OKRs (Objectives and Key Results). Hoshin Kanri and OKRs are both goal-setting methodologies designed to align strategic objectives with execution, however they differ in structure, deployment, and emphasis. Hoshin Kanri is a long-term, structured approach originating from Japan, primarily used in lean management. It focuses on achieving breakthrough objectives through a systematic cascade of goals, using the “catch ball” process to ensure alignment and commitment across all levels.

OKR is a more flexible and agile methodology, originating from Silicon Valley, designed for rapid execution and adaptability. OKRs consist of qualitative objectives paired with measurable key results, typically set on a quarterly basis to drive ambitious, short-term achievements. The framework encourages stretch goals, risk-taking, and iteration, making it better suited to Argentina’s dynamic economic environment.

KPI Tree. From strategic (left) to operational (right)

At the highest level, senior leadership set ambitious yet achievable objectives that defined what the organization aimed to accomplish. These objectives are broad, qualitative statements such as “Achieve world-class safety performance”, “Maximize operational efficiency”, and “Develop a culture of continuous improvement.” Each of these objectives was paired with key results, which are specific, measurable outcomes that indicate progress toward the objective.

Once the company-level OKRs were established, the process moved into the cascading phase. This involved Shinka Management supporting iterative discussions with executives, managers, chiefs, coordinators, and leaders to refine objectives and key results.

Managers translated these into departmental OKRs, such as:

- “Improve Overall Equipment Effectiveness (OEE) from 65% to 80%”

- “Reduce unplanned downtime by 25%”

Team leaders further broke down these objectives into actionable goals, embedding OKRs into daily routines and boosting accountability across the company.

Communication (Again)

When implementing a transformation, especially an operational excellence or lean management transformation, we usually modify processes, routines, work environments, and even organizational structures. These changes, while intended to drive efficiency and improvement, inevitably alter the way people work on a daily basis. As human beings, we have a natural tendency to resist change – some more than others – but resistance is always present to some degree, as it challenges established habits, comfort zones, and familiar ways of doing things.

In terms of communication of objectives, simply announcing ambitious numbers and demanding revolutionary approaches to achieve them can backfire. This approach often leads to decreased motivation, lower performance, unsustainable improvements, and ultimately, suboptimal outcomes. When people perceive that targets are imposed from above without explanation or engagement, they feel disconnected from the process, seeing the objectives as arbitrary mandates rather than meaningful goals. This can create frustration, reluctance, and even passive resistance, undermining the very transformation efforts that the organization is trying to drive.

Well aware of these challenges, Daniel worked closely with Escorial’s top and middle management to ensure that objectives were effectively communicated throughout the entire organization. The key was not just to present the numerical targets but to articulate the deeper purpose behind them, linking each objective to a broader goal. By helping employees understand how their work contributed to a greater goal, they developed a sense of awareness, ownership, and personal investment in the transformation. This approach significantly reduced resistance to change, as people no longer felt that the transformation was something being forced upon them but rather an opportunity they were actively contributing to, fostering motivation and engagement across all levels of the company.

Establishing a Systemic Approach

With the KPIs for each area defined and efficiently communicated, the next step was to understand the current state of each area. Daniel emphasized the importance of establishing routines to create a systemic approach, rather than relying on one-off efforts.

Leaders were trained to implement critical routines, standardized in the agendas of strategic leaders, middle management and team leaders, such as:

- Genba Walks | Regular visits by management to the shop floor to observe processes firsthand, identify opportunities for improvement, and engage with staff

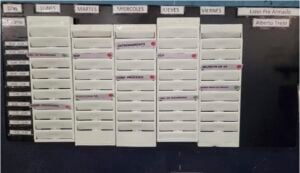

- Asakai Meetings | Short, daily morning meetings held on-site to review performance, discuss issues, and align the team for the day ahead

- Kamishibai Boards | Visual control boards used to track tasks and ensure processes are being followed according to standard

However, operational challenges – like equipment issues and production delays – threatened to derail progress. Escorial’s leadership stepped in, supporting team leaders in managing both urgent issues and long-term improvement tasks. The leadership sent a clear message that running after what was urgent was a consequence of not dealing with what was important.

Weekly schedule for a Supervisor including genba walks and henkaten/asakai meetings

Daniel introduced the team to a tool that he had used in a lean transformation in mining, the “standardized agenda” or WILO (Week In the Life Of). Through WILO, leaders could secure time in their agendas for the routines defined for each role and organize the rest of their activities in the time remaining, having already allocated time to deal with the most important tasks.

At the strategic level, the standardized agenda was based on routines that include monthly strategy deployment reviews, direct engagement with middle management, and visits to operational areas to reinforce leadership presence, provide direction, and gather direct feedback from employees.

Kamishibai Task Board

For middle management, WILO was designed to balance time between performance monitoring, coaching, and problem-solving. This included daily participation in asakai meetings, and time for genba walks to observe processes firsthand and identify improvement opportunities. Additionally, a portion of time was devoted to reviewing kaizen initiatives, ensuring that problem-solving activities are aligned with broader business objectives.

At the shop floor level, the standardized agenda revolved around the kamishibai board ensuring that team leaders dedicate time to frontline engagement, 5S, problem identification, problem solving, and adherence to standardized work.

By structuring time effectively at each level, the team created a disciplined approach to leadership engagement, ensuring that efforts are consistently directed towards strategic goals, operational execution, and cultural development.

Visual Management

The Escorial Production System had finally begun to have a presence on the shop floor. Daniel stressed the importance of creating awareness among associates, not only with regards to the defined targets, but also related to the current status of each of the performance variables in play. The goal of the Escorial team was to start implementing visual management tools that allow leaders to have a real-time understanding of the current situation on the shop floor, allowing appropriate and timely decision making. Further, they wanted to ensure that these visual management tools would be easy for everyone at the genba to follow.

Performance Meeting

Having a visual management tool like a KPI board is worthless if no-one uses it. After Daniel challenged the team with a few questions about how to address important topics each day, Escorial’s deployment team decided to define and implement a structured five-minute morning meeting at the start of each shift.

These meetings aimed to foster alignment amongst teams and drive continuous improvement through focusing on:

- KPIs and current status

- Priorities, and deviations or changes in operations (henkaten)

- Operator concerns and improvement ideas

The team noticed from the very beginning that this meeting created a habit of shared responsibility and accountability and helped them to stay engaged and proactive rather than reactive.

The team leaders quickly embraced this, pointing out that one of the main advantages of it was that the structured communication routine ensured that critical information flows efficiently inside the team and from one level of the organization to another.

As the kitchen assembly supervisor noted, “it allows for quick problem identification, enabling immediate countermeasures to be discussed and actioned. Operators can raise concerns, share observations, and propose improvements in real time, which fosters engagement and a sense of ownership over their work environment”.

Daniel and the implementation team agreed that a key element that enhances the effectiveness of these meetings was the use of a user-friendly KPI board, particularly one that is manual, flexible and adaptable (mainly in early adoption times) relying on pen and paper rather than digital solutions. This simplicity makes the information easily accessible to everyone, regardless of their technical skills, and encourages ownership and active participation. Daniel helped the Escorial team noticing that when operators and supervisors physically update and interact with the board, they develop a deeper understanding of performance metrics and their direct impact on daily operations. The act of writing numbers, noting issues, and marking progress reinforces awareness and creates a stronger connection with the data. Furthermore, it eliminates reliance on technology that could create barriers to quick updates and discussions.

Genba Walks

One of the routines scheduled on the leaders’ agenda was the famous Genba Walk. Although this was something that the Escorial team was not used to, they got on board quite fast once they understood and saw the tremendous number of benefits that it provides. Managers and leaders realized that a key advantage of being present on the shop floor is the ability to address issues as they arise.

Direct contact with the genba gives us a real view of what’s happening and accelerates sound decision-making. This is where solutions that really work are generated.

Agustin Donamari – Industrial Manager

Daniel expanded on this observation: “Handling issues directly on the shop floor allows leaders to make well-informed decisions and provide precise instructions based on firsthand observations, which contrasts with decision-making in meeting rooms, where management may receive a filtered or skewed version of events, leading to ineffective countermeasures that fail to address the actual root cause of a problem.”

It was impressive to see the increase in the level of adherence to this routine across Escorial’s leaders. In the beginning, the top management’s level of adherence to this routine was low at around 30%. Very quickly, with a combination of self-willingness and requests coming from the shop floor in the form of Argentinian-very-low-professional-distance demands like “Hey!… come and see this” or “Why are you not visiting us? We miss you!”, everyone came to understand that the genba walk dynamic was helping not only from a performance point of view but also from a teamwork and cultural perspective. The president, no less, started with 100% support, which obviously encouraged the rest to follow suit.

Current Status – Zooming In

Motivation was high and the team was hungry to start improving processes across both plants. At this point, however, Daniel felt the need to play the role of the “wet blanket,” informing the team that they had an important task to achieve before they started improving. Daniel presented the team with an essential question: “How do we know if we are improving?” After a few vague “because-the-numbers-are-going-up” type answers, the team eventually turned its attention to standards – the foundation of lean.

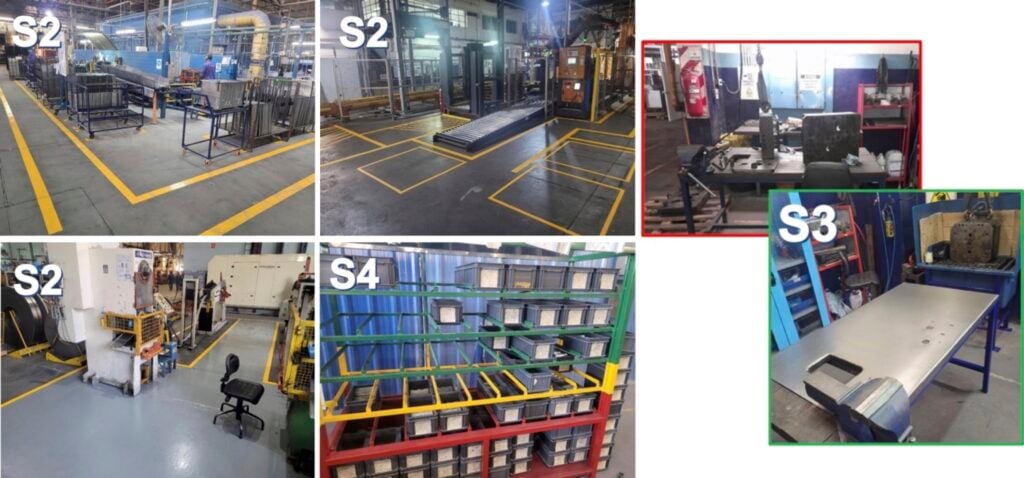

5S

5S wasn’t a new topic for Escorial. Efforts in implementing 5S had been made before, however those efforts had not been sustained beyond general house-keeping activities. Having a safe, friendly, and standardized workplace where abnormalities could be easily identified was now a key goal of the team. Applying the same approach to thinking as used when analyzing a process, the Escorial team concluded that understanding the current status of the workplace is important, and that for judging the workplace’s status, a standard would be required; and this could be achieved through thoroughly implementing 5S.

5S Basics

5S is a workplace organization method that focuses on creating and maintaining a clean, orderly and efficient environment. It aims to improve safety, productivity and quality by establishing visual order and discipline, through the folllowing five steps:

- S1 | Sort

- S2 | Set in Order

- S3 | Shine

- S4 | Standardize

- S5 | Sustain

Initially, as is typical in a production-driven environment, gaining associates’ commitment to dedicating effort to 5S was challenging. However, Escorial’s top management continued to drive and support the implementation of 5S by setting the example, which led to significant improvements at both the 25 de Mayo and Suipacha plants – particularly in operations, maintenance, warehouse, and quality – with a strong focus on S2 (Set in Order), S3 (Shine), and S4 (Standardize).

Implementing 5S is not a technical challenge; it is a cultural one. The first three steps – Sort, Set in Order, and Shine – were completed relatively quickly. Daniel coached Escorial top and middle management, stating that the true test of 5S lies in the last two steps: Standardize and Sustain. These steps require ongoing discipline, engagement, and leadership commitment to change everyone’s mindset from viewing 5S as a one-time project to recognizing it as a continuous journey.

Escorial implemented a cross-area 5S auditing system that not only brought in fresh eyes to evaluate each area objectively, but also served as a platform for sharing best practices, learning how others address 5S challenges, and identifying areas in need of support. The system fostered healthy competition between departments by recognizing high performers and directing support to those requiring improvement.

Daniel coached Escorial’s top management on the following key behaviors:

Demonstration of commitment to 5S through actions: consistently reinforcing the importance of 5S and holding themselves accountable to the same standards.

Integration of 5S into daily work: 5S should not be considered as a separate initiative, but instead should be treated as an integral part of everyday operations.

Fostering a culture of accountability and pride: recognizing and celebrating successes while addressing gaps with firmness and support.

Auditing and improvement: essential to ensuring that 5S standards are maintained and continuously improved. These go beyond checklists, focusing on the behaviors and mindsets that underpin 5S.

Such is the commitment of the top management with 5S that for 2025, 5S became a key OKR with short, medium and long term goals. It is expected for 2025 that audit result for both plants reach at least 75%. Also, although not the most important aspect of this OKR, it is part of the calculation of the annual bonus for employees.

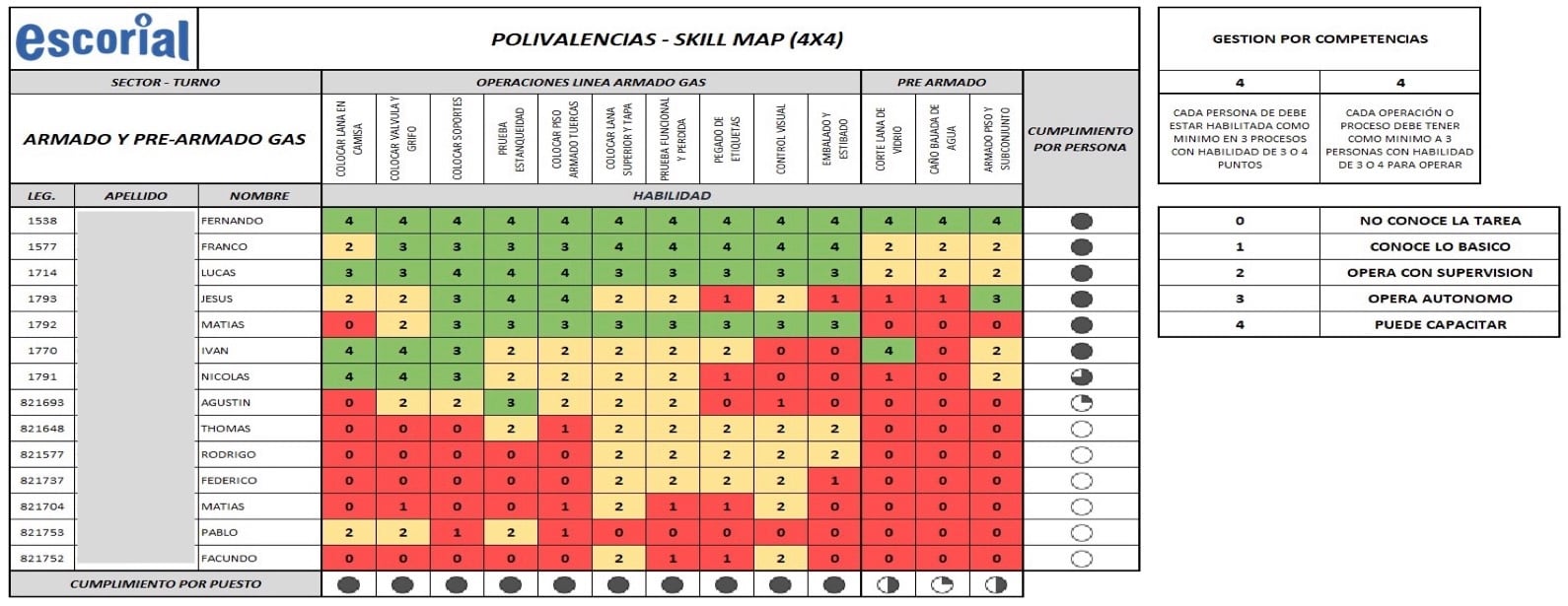

Standard Work

Having put the foundations of understanding the current state in place, the team started analyzing their manufacturing processes from a standardization perspective. From the shop floor, the team leaders, together with the quality and operational excellence teams, commenced an aggressive standardization plan for both Suipacha and 25 de Mayo plants.

This marked a significant step forward – equipping leaders with a tool to train operators, providing operators with a reference for troubleshooting, and enabling production supervisors to begin developing skills matrices in collaboration with HR. The introduction of skills matrices proved particularly valuable, helping Escorial enhance operator capabilities, structure training plans, and improve workforce flexibility through more effective operator allocation.

Skill matrix indicating the level of competence of each associate (0 = doesn’t know, through to 4 = can train others). Target (4×4): 4 associates with a score of 3 or more per workstation & each associate able to work in 4 or more workstations.

TPM – Autonomous Maintenance

As standardization progressed, waste and losses within processes became easier to identify. When analyzing capital intensive processes, the team quickly realized that taking good care of the equipment would prevent most of the loses they were experiencing associated with machinery performance.

At this point, Daniel introduced TPM (Total Productive Maintenance). Although TPM wasn’t an unknown term for some people at Escorial, they all agreed with the need to improve their capability and introduce this methodology step by step in order to tackle losses associated with their processes.

The team designed the following step-by-step plan that allowed them to embark on the TPM journey:

- TPM training

- Autonomous maintenance training

- TPM team creation

- Recording of losses and stoppages

- Safety mapping

- Establishment of KPIs and targets

- TPM board implementation

- Deep cleaning

- Auditing

The Escorial team were always conscious of the need for a shift in mindset away from seeing machinery as merely equipment that operators use to recognizing it as an integral part of the manufacturing process for which they share responsibility. Traditionally, there is a clear divide: operators focus on production, and maintenance teams handle equipment upkeep and repairs. This separation existed at Escorial and often led to inefficiencies, as operators did not feel accountable for the condition of their machines, and maintenance teams lacked real-time insights into how the equipment was behaving during daily operations.

Machine Safety Map

Daniel’s support focused on dismantling this divide by fostering a sense of ownership among operators, encouraging them to take proactive care of the machinery they work with. Instead of the prevailing attitude of “I only use it, and it is the maintenance team’s responsibility to take care of it,” the team embraced the principle that operators and maintenance personnel must work together to ensure optimal equipment performance. Operators were trained not just to use the machines but to understand their basic functions, detect early signs of wear or failure, and carry out routine maintenance tasks. This involvement not only reduced unexpected breakdowns but also led to a deeper connection between the workforce and their tools, improving both efficiency and morale.

TPM – KPI Board

By integrating this shared responsibility into daily routines, Escorial started creating a culture where equipment reliability is a collective goal rather than a segmented task. Maintenance teams were thrilled with this approach as well since it allowed them to focus on higher-level technical improvements and predictive strategies instead of being overwhelmed with reactive repairs. On the other hand, operators started developing a greater appreciation of the role that well-maintained machinery plays in production efficiency and safety.

Given the importance of the Comprehensive Maintenance system, management has set another key objective: the implementation of Level 1 Maintenance on critical machines in both plants by 2026.

Lean Transformation – Progress Check

After fifteen months of disciplined effort spanning August 2023 through October 2024, it became clear that Escorial’s commitment to its lean transformation was delivering tangible and measurable results. The implementation of the Escorial Production System (EPS) across both operational sites – 25 de Mayo and Suipacha – marked a significant step forward not only in operational effectiveness but also in the overall lean maturity of the organization.

At the start of the journey, a baseline assessment revealed relatively low lean maturity levels, with the 25 de Mayo plant scoring 15% and Suipacha 19%. These scores reflected the early stages of lean adoption, where practices were scattered and disconnected from broader strategic intent. With the deployment of the EPS, both plants began to evolve in their understanding and application of lean principles.

By October 2024, the 25 de Mayo plant had progressed to a lean maturity level of 36%, while Suipacha reached 33%. These numbers represent more than a doubling of lean maturity in 25 de Mayo and a substantial gain in Suipacha, showing a clear trajectory toward excellence. As the maturity levels increased, so did the coherence and consistency in how lean was practiced across the organization. Initiatives were no longer isolated or sporadic; they became synchronized efforts that reinforced one another. These facts were confirmed by the lean maturity assessment’s results when analyzing the effort balance between the Alignment, Understanding, Improve, and Sustainability dimensions. This balance fostered an environment in which continuous improvement became part of the daily routine rather than a special event.

I’ve been at Escorial for 20 years, and in recent years I’ve witnessed a remarkable transformation. One of the most impactful changes has been the implementation of 5S. It didn’t just improve order and cleanliness in our sector – it also influenced my daily life at home. I began to see things differently.

When I first joined, everything was centered around production. Today, it’s also about people – understanding what the team needs and working with the environment. With the arrival of Shinka and the Escorial Production System (EPS), we began using tools that helped us organize more effectively and view problems from a new perspective.

Now, in our sector, we can identify problems and carry out RCA (Root Cause Analysis) to solve them, and pass that mindset on to operators – something that didn’t happen before. The TJI (Training on the Job) method also changed how we support new employees: the focus is now on safety and comfort, not just results.

Thanks to this project, I feel like I come to work each day not only to learn, but also to teach. There’s still much to improve, but now we have a clear direction. We can finally see the horizon – we know where we’re going, and we understand that this is the path forward.

Alberto “Beto” Trejo – Pre-Assembly Supervisor

Sustaining Continuous Improvement

Although the “Sustain” stage is typically seen as the last step of a lean transformation, in the case of Escorial, it was developed and built into every stage of the implementation program, through creating standards, establishing routines, and improving leadership behavior.

Beside fostering continuous improvement aligned with the goals of the organization through focusing on gaps in the KPIs, there are also tools and systems that can further encourage sustained involvement with kaizen. Escorial chose to establish a kaizen suggestion scheme and quality circle activities.

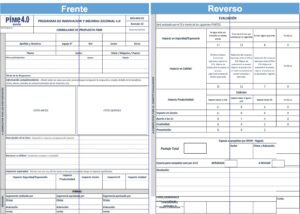

Kaizen Suggestion Scheme

Escorial created “PIME 4.0“, a well-structured Kaizen Suggestion Scheme that plays a critical role in sustaining continuous improvement, fostering employee motivation, and generating an exponential impact on organizational benefits. By providing a formalized mechanism for employees to propose, develop, and implement improvement ideas, PIME 4.0 ensures that continuous improvement becomes an ongoing and ingrained practice rather than a temporary initiative.

Kaizen Suggestion Form

The name itself reflects the program’s emphasis on Participation, Innovation, Methodology, and Execution, while “4.0” signals its alignment with modern manufacturing practices and digital tools. This initiative was structured to involve operators, supervisors, and managers, ensuring that improvement ideas originate from those closest to the processes and are evaluated by a cross-functional team that can drive their implementation.

The sustainability of continuous improvement doesn’t depend solely on leadership, nor is it something that can be delegated or left to chance. For this culture to truly take root in the organization, it is essential to have the active and ongoing participation of employees at all levels, from the plant floor to senior management.

A structured suggestion system plays a key role: it provides a clear, accessible, and motivating space for everyone to express ideas, concerns, and proposals for improvement. This not only drives innovation and allows for early identification of opportunities, but also reinforces a sense of belonging and commitment.

When employees see their contributions being heard and implemented, they feel part of the change. And when that change is valued, their enthusiasm multiplies. A good system also ensures that the most impactful ideas are prioritized and executed effectively, generating real and sustained benefits.

Ultimately, true continuous improvement is born from collaborative work between leadership and teams, supported by tools that promote communication, shared responsibility, and the ongoing pursuit of excellence.

Juan Silvani – HR, IT & Finance Manager

The process begins with employees submitting their improvement proposals based on firsthand observations and challenges they encounter in their daily work. These suggestions range from small adjustments to workflow organization to more complex process optimizations. To maintain a structured and results-driven approach, each idea is reviewed by a dedicated evaluation team composed of representatives from different functions, including production, maintenance, quality, safety, and continuous improvement. This team assesses the proposals based on predefined criteria such as their impact on safety, productivity, cost reduction, 5S implementation, and product quality.

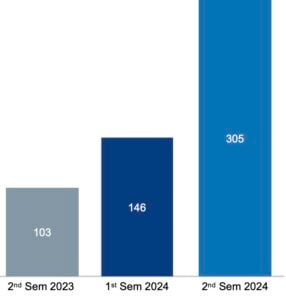

Number of kaizen suggestions

It’s truly motivating to see our employees’ active participation in the PIME 4.0 program, as it demonstrates how the culture of continuous improvement is permeating the organization. The growth in the number of PIMEs submitted constantly challenges us, both in their management and in our focus on providing the necessary resources for their implementation. Furthermore, we found it very interesting to design a recognition system for these implemented ideas, one that monitors the maturity of the SPE and is key to motivation, where everyone can see the tangible benefits of their participation. In this sense, we see how employees integrate the generation of improvement ideas into their daily work, as they can then see them implemented in their jobs. This fills them with pride, both for the value provided and for feeling heard and seeing the changes taking place. Without a doubt, the Continuous Improvement Team has progressed and developed significantly since the implementation began, and Daniel Andreu’s guidance has been key throughout this process. We are convinced that we are on the right path and that we must continue moving forward, strengthening our culture of continuous improvement, based on the development of all the people who are part of Escorial.

Agustin Donamari – Industrial Manager

Ideas that demonstrate strong potential for positive impact are prioritized for rapid implementation.

The Escorial team established the Kaizen Suggestion Scheme as the driving force behind a continuous improvement cycle – where each improvement builds on the last, creating a compounding effect that allows the organization to evolve steadily without the need for external interventions.

Quality Circles

There are several ways for an organization to systematically drive efforts to sustain a continuous improvement culture. Quality Circles (QC) is one of these approaches. The Escorial Continuous Improvement Team was keen to commence the QC journey. While recognizing the importance of QC, the top management hesitated to proceed down the QC path, due to their view that Escorial’s lean maturity level was insufficient at the time. However, they also considered that preventing the enthusiastic team from moving forward would negatively affect their motivation and, looking at the defect KPIs, they could see a lot of opportunity for improvement. This perspective gave Escorial the right “mood” to start with Quality Circles, recognizing that lean is a tool to reach their goals.

Quality Circles and Kaizen Suggestion Schemes both aim to drive continuous improvement in a manufacturing company, but they differ in their structure, approach, and level of employee involvement.

Rooted in the principles of participatory management, quality circles empower workers by giving them a voice in decision-making, fostering teamwork, and enhancing problem-solving skills.

“Patience,” Daniel urged, encouraging the team to resist the urge to jump to conclusions or quick fixes, and to trust in the systematic approach the methodology provides. With that in mind, employees came together regularly to discuss operational challenges, inefficiencies and quality concerns. Using problem-solving tools such as the PDCA (Plan-Do-Check-Act) cycle, cause-and-effect diagrams, Pareto analysis, and the 5 Whys method, they identified root causes and proposed solutions.

Management support was crucial in facilitating this process by providing necessary resources and recognizing successful initiatives. Escorial top management acted as the “evaluator panel,” and often couldn’t help themselves from jumping in and providing support to the teams when needed

During Q3 and Q4 of 2024, thirty-one QCs were presented from which the top management selected eight to participate in the final competition. For 2025, those numbers are on track to triple.

The Quality Circle event was held in December 2024, with the winner going on to participate in the 2025 Argentina National QC Convention.

During the QC event, Daniel remarked that beyond operational gains, quality circles play a fundamental role in fostering a culture of continuous improvement. By encouraging regular discussions about work processes and potential enhancements, they help embed kaizen principles into the organization’s DNA. This is critical for long-term organizational success, as it ensures that improvement efforts are sustained rather than being dependent on top-down initiatives.

As Head of Continuous Improvement, seeing the growth of teams from within is what motivates me most. Many employees who had never faced these types of challenges are now not only encouraged to present their ideas, but they do so with pride, commitment, and solid proposals. The Quality Circles demonstrated that continuous improvement is not…

It was a different experience, one that took us out of our routine and made us grow. Being able to contribute a real improvement, present it to the entire management team, and feel heard taught us something that goes beyond work. I hope everyone at the plant can experience something like this.

The A3 method helped us think differently. New ideas began to emerge, some of which became proposals for improvement. Before, many solutions were temporary, and problems kept returning. Today, we seek to solve them from the root causes.

Before, we focused only on our own interests. Today, through this project, we’re beginning to notice things we hadn’t seen before—situations originating from other sectors, which we now feel a part of as well. We’ve stepped out of our comfort zone and learned to truly analyze problems.

At first, we didn’t understand much. We were starting from scratch; everything was new. But with the guidance of the leader and his assistant, we learned by doing, and we ended up presenting our work to management. It was a very valuable experience.

I’m studying, and I knew something about oral presentations, but being able to show what we did in front of the entire management team was something completely different. I wish more colleagues had the opportunity to experience this. It challenges you, makes you grow, and shows you that you can always contribute something more.

Conclusion

“Kaizen is only for Japanese people, here the culture is different” … “Lean is only for the automotive industry” … well, here is another example that proves this to be wrong. The transformation of Escorial through the implementation of lean principles, has had profound and far-reaching effects on both the company’s operations and its corporate culture. By integrating lean thinking into the organization’s core processes, Escorial was able to achieve remarkable improvements in safety, operational efficiency, quality and delivery performance while fostering a deep-rooted cultural shift that involved all employees, from top management to shop floor associates.

From a practical point of view, one of the key successes of the lean transformation at Escorial was the thorough implementation of 5S, which provided a strong foundation for organizing the work area, improving safety, and making issues easy to detect. By establishing standards, visual management, and daily routines, Escorial created a work environment that was oriented to continuous improvement. This organizational “clarity”, enabled better communication and collaboration across teams, leading to increased accountability and a stronger sense of ownership at every level of the company.

Daniel’s involvement was a fundamental driver of this transformation. As a highly engaged champion of lean, Daniel played a crucial role in helping Escorial top management to align the entire organization behind its vision and use lean to move towards it. He worked closely with the team to ensure that lean principles were not just adopted at the operational level but were also embraced strategically at the highest levels of the organization. His leadership was key in supporting Escorial with securing the necessary resources and driving the persistence needed for a successful transformation. Daniel’s commitment ensured and convinced Escorial that this lean journey was not seen as a temporary initiative but as a critical component of Escorial’s long-term strategy.

When you begin implementing lean, and high expectations are set by the project support team – in this case, Shinka Management – it’s almost inevitable that some skepticism will be expressed on the other side. For the Escorial team members who had participated in the Lean Japan Tour, there was no doubt that lean was the way forward. However, the vast majority of staff had not been to Japan, and in most cases hadn’t even witnessed lean in action in other companies. Despite this, they constructively decided to “take a leap of faith,” and boy did they!

The management never stopped providing the direction, support, and accountability needed to steer the organization through the challenging aspects of the transformation whilst always having an open mind regarding change management. Top management’s role in setting clear expectations, participating in problem-solving activities, and leading by example reinforced the importance of lean, boosted motivation and created a culture where continuous improvement became ingrained in Escorial’s daily operations.

October 2024: New higher lean maturity supported by well-balanced efforts accross all dimension of the lean transformation.

All numbers went up – safety, quality, productivity, efficiency, delivery – and some of them with significant improvement. But perhaps one of the most valuable outcomes of Escorial’s lean transformation was the shift in organizational culture. Escorial’s leadership played a critical role in fostering an environment of trust, openness, and empowerment, where employees felt encouraged to contribute with ideas. The company now operates with a mindset that views challenges as opportunities for growth, and where employees take pride in the collective success of the organization.

Escorial aimed to prepare for generational change by cultivating new leaders who embraced continuous improvement as a core value. This involved mentoring programs, leadership development initiatives, and the establishment of frameworks to pass on lean knowledge and practices to future leaders.

By creating and implementing the Escorial Production System, Escorial has equipped itself with the tools and mindset to adapt to market fluctuations (a constant in Argentina) and technological advancements, ensuring its continued growth and success.

Finally, the lean transformation at Escorial is a powerful testament to the effectiveness of lean principles when implemented thoughtfully and consistently across an entire organization. Through a combination of strategic initiatives, employee engagement, and leadership commitment, Escorial has not only enhanced its operational performance but also created a sustainable culture of continuous improvement.

This transformation serves as a valuable model for other organizations embarking on a similar journey, demonstrating that, when effectively supported, led, and implemented, lean transcends cultural, linguistic, and industry boundaries – driving not only process improvement but also holistic, long-term organizational transformation.

About the Author

Juan Bertero is the LATAM and EMEA Regional Manager of Shinka Management, a lean training and consulting firm with clients in over 70 countries. Juan developed his lean know-how from the Japanese company DENSO, a Toyota tier 1 supplier, and he keeps his knowledge and passion growing. Based in Italy, he is supporting European, Middle East and South American manufacturers within manufacturing, FMCG, pharma and mining industries, among others.

People development

People development