Explore Innovation in Prefabricated Housing and Lean Construction in Japan

Join a global delegation of housing and construction professionals for a study tour of Japan’s world-leading building sector. Discover how Japan is tackling global housing challenges with precision, efficiency, and sustainable innovation.

The Shinka Management Japan Housing Mission offers a unique opportunity to gain firsthand insights into one of the world’s most advanced housing markets.

This one-week housing industry study tour in Japan is designed for senior leaders in construction, housing development, government, and supply chain management. Participants will explore Japan’s prefabricated housing and building product sectors through site visits, executive seminars, industry networking and cultural experiences.

With a focus on prefabricated and modular building, lean construction and kaizen, and modern methods of construction, the study tour showcases the practices and technologies that have enabled Japan to lead in housing quality, speed, and sustainability.

Since 2007, Shinka Management has hosted clients from over 70 countries on professional development tours to Japan. This program builds on that expertise, with leadership from bilingual consultants and support throughout the journey including interpretation, cultural guidance, domestic travel, meals, and accommodations.

Japan Housing Mission – Program Details

Dates: 12 – 18 April 2026

Program commences at 3:30pm on the starting Sunday in Tokyo and concludes the following Saturday in Tokyo with an optional day of sightseeing

Inclusions: Accommodation, meals*, domestic transport, factory tours, seminars, networking and cultural visits | *Meals exclude two free evenings and Saturday lunch

Registration Fee: USD 6,750

Itinerary and Registration: Contact Shinka Management to request brochure and registration form, itinerary and factory details via the form below.

Japan Housing Industry Study Tour – Program Highlights

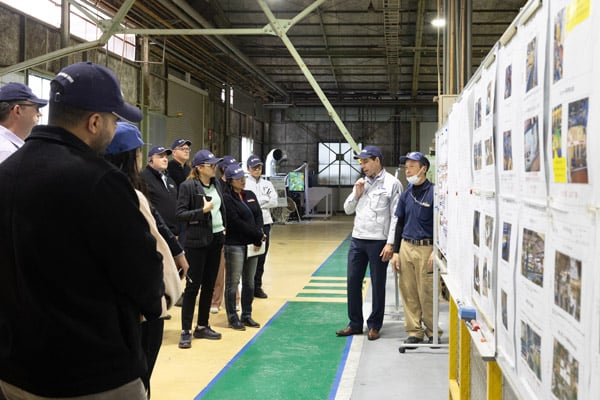

Experience an immersive, on-the-ground look at Japan’s prefabricated housing and building materials sector, featuring shop-floor factory tours, expert-led seminars, and direct engagement with industry leaders.

Prefabricated Housing Factory Tours

Visit leading-edge production facilities specializing in modular and prefabricated housing. Observe automated assembly lines, advanced manufacturing systems, and high-precision quality control in action. Learn how Japanese industrialised housing companies are achieving speed, efficiency, and customization at scale.

Modern Methods of Construction

Discover how Japan’s housing industry is redefining construction through advanced modular, panelised, and volumetric building systems. Learn how off-site manufacturing, digital design integration, and precision assembly are improving speed, quality, and sustainability. See how industrialised construction methods are enabling scalable, efficient housing solutions for the future.

Building Products and Appliance Manufacturers

Gain insight into how Japan’s top manufacturers of home fixtures and appliances apply lean manufacturing and continuous improvement principles to achieve world-class levels of productivity, quality and safety across the supply chain.

Customized Residential Construction Systems

Explore production systems designed for made-to-order housing, enabling high levels of personalization while maintaining operational efficiency. Learn how companies manage complex production flows, balance loads, and deliver consistent quality in a high-variation environment.

Seminars and Industry Networking

Engage with Japanese housing and construction industry stakeholders through seminars and roundtable discussions. Gain insight into current industry trends, challenges, and innovative approaches, while building valuable international connections with peers and experts.

Lean and Kaizen Training

Participate in seminars on lean construction and continuous improvement culture led by Shinka Management’s experienced consultants. These sessions provide context for what you’ll observe on site and equip you with frameworks to apply within your organization.

Cultural and Business Insight

Begin your journey with a Japanese business etiquette seminar and experience Japan’s rich cultural heritage throughout the week. Enjoy traditional cuisine, regional sightseeing, and immersive experiences that help deepen your understanding of Japanese society and customer expectations.

Délégation Sfax Ville, Sfax, Tunisia

First of all, I want to express my sincere gratitude for this unforgettable trip. From the beginning, the level of organization and attention to detail was outstanding. The program was well thought out, providing a perfect balance between plant visits, theoretical training, and practical experiences. It’s evident that a lot of thought and effort went into ensuring the satisfaction of the participants. I return to Tunisia with a wealth of information about the culture and etiquette of Japan, and it has inspired me to delve even deeper into the rich history of this fascinating country.

One of the highlights for me was the discovery of the Toyota Commemorative Museum, the practical training center, and the Gifu Auto Body Toyota HiAce final assembly plant. The visits to Toyota Boshoku Seiko, GI Service, Suzaki Industries, and AVEX were truly enlightening. Many concepts about lean management that I previously misunderstood were clarified, and obtaining information from the source was enriching. I must also commend the selection of hotels, which were not only comfortable but strategically located, providing easy access to explore the surrounding areas. The choice of restaurants and the diverse culinary experiences incorporated into the trip were exceptional.

I am typically hard to impress, but this time was an exception. Thank you for orchestrating such a fantastic tour and I would not hesitate to recommend Shinka Management services to colleagues and friends.

read more

Hobart, Tasmania, Australia

Paul Smith and the team at Shinka Management, in particular Eri Dennis, did an incredible job planning and leading our tailored Japan Study Tour in March 2024. Our team of construction and training professionals learnt and more importantly experienced so much about lean management and Japanese construction, manufacturing and factory practices. Without the expertise and knowledge that Paul and Eri brought to our tour we would not have had the exposure and depth of learning that we had. It was an incredible study trip and we are bringing back so many important learnings that we will implement into our modular homes project. Having Paul with us throughout the tour to interpret and lead was invaluable – his understanding of Japanese business practices and culture was critical to the success of our trip. Eri’s connections to factories and businesses in Japan ensured that we were able to get tailored factory and plant tours which enabled us to experience lean management in practice. Our tour had an excellent blend of theory, practice and exposure. We are incredibly grateful to the team at Shinka Management. I can recommend Shinka Management to other organisations who seek to understand and experience lean management practices in Japan.

read more

Milton, New Zealand

If you have embarked on a lean journey The Lean Study Tour should be on your bucket list!

It was inspiring to see the Toyota Production System in action as a management system, as well as the small improvements made day in and day out by dedicated and motivated teams all striving to continuously improve. Paul, Ben, Tony and Juan (tour leaders) did an outstanding Job of guiding us through Japan, and highlighting where TPS is improving society as well as manufacturing. Their subtle lines of questioning and coaching combined with observing TPS in action and the instruction of Japanese Sensei inspired tour participants on how they can effect change.

Every detail from transport to meals and accommodation were professionally managed and executed. Practical learning environments such as the Toyota group training center consolidated class room learning with hands on experimentation which lead to real “ah ha” moments with many tour participants.

This tour was an extremely rewarding and enjoyable learning experience. I highly recommend the Lean Study Tour.

read more

Western Sydney, New South Wales, Australia

Wow. What a great experience not just from a learning perspective but also a great cultural experience as well. From the start the group came together really well. It was a perfect mix of practical and theory, and to gain an insight into the Toyota Production System and see it in action at all the sites we visited this week was awesome. A big thank you to Ben for making everyone feel so warm and making the week run smoothly. Over the week I have seen there are so many opportunities for myself and my company to improve. Now I’m heading back to implement what we have learnt and will take small steps to achieve our ultimate goal as a business. This is a wonderful investment personally and for the company. In six months’ time I want to look back at this trip and show how much it has made me achieve.

Finally, to spend time with Yamashita Sensei and get hands-on insights into the Toyota Production System was an eye-opener and an experience I will never forget. Great tour with an awesome bunch of people.

read more

Sydney, New South Wales, Australia

Dear Paul, Ben and Eri,

We would just like to take a moment to thank you for such a wonderful tour. You exceeded all our expectations for a week long journey – from your very professional approach and even more personal service. The week was extremely insightful, and we could not stop talking about what we were going to do when we returned home.

Each plant tour, Q&A and debriefing were all very professional and informative. These taught us so much to help us move forward on our lean journey. Not only were the days very enjoyable but the nights were fantastic and fun. We learned so much about lean as well as experiencing the Japanese culture and the wonderful people.

Since we have been back the four of us have been very quick and extremely effective in rolling out many Kaizen improvements, setting takt times, 5s’ing many areas and much more (fantastic work). I’ve had much time to reflect and think about the tour and our next steps. We’ve written a training manual in 4 modules and have just completed the first module of training through the entire company.

We certainly have a new buzz flowing in and around the company and looking forward to this wonderful journey. Full credit to all of you. This has been the best tour we have ever been a part of and we will be sending more of our team in the future.

read more

Who Should Attend

This study mission is designed for professionals and organizations involved in the planning, design, manufacture, and delivery of housing. It is particularly relevant for those seeking to improve construction productivity, adopt industrialized building methods, or explore lean construction practices.

Participants will include decision-makers and leaders from across the global housing and construction ecosystem, including:

- Homebuilders and residential construction executives

- Government housing departments and regulators

- Building product manufacturers and suppliers

- Modular and prefabrication specialists

- Industry associations and policy makers

- Operations, supply chain, and lean professionals in the housing sector

Benefits of Joining a Japan Housing Industry Study Tour

The Japan Housing Mission offers a transformative professional development experience designed specifically for leaders and innovators in the global housing and construction sector. Through immersive site visits and direct engagement with Japan’s most advanced housing manufacturers and suppliers, you’ll gain a firsthand understanding of lean construction, industrialized building systems, and the continuous improvement culture that underpins Japan’s housing success.

You’ll observe how Japan consistently delivers high-quality, energy-efficient homes through precision manufacturing, modular design, and supply chain integration. From factory genba walks to in-depth conversations with senior executives and housing experts, you’ll uncover proven strategies for increasing productivity, improving quality, and reducing waste across the building lifecycle.

Throughout the week, you’ll be supported by Shinka Management’s team of bilingual consultants—experts in lean manufacturing and Japanese business culture—who will provide interpretation, context, and coaching to help translate each site visit into meaningful insight for your organization.

A key strength of the program is the opportunity to build valuable connections within a global peer network. You’ll engage with fellow participants from across the housing ecosystem—including builders, suppliers, regulators, and developers—sharing experiences, challenges, and ideas that extend well beyond the tour itself.

By the end of the mission, you’ll return home inspired and equipped to lead innovation in your organization, with a deeper understanding of how Japanese management principles can be adapted to address today’s housing challenges—from supply shortages and labor constraints to sustainability and customer satisfaction.

Housing and Construction in Japan

Japan’s housing industry faces many of the same pressures challenging the global construction sector: an aging workforce, rising material and labor costs, tightening regulations, and the urgent need to deliver high-quality, sustainable housing at scale. Like many countries, Japan must reconcile increasing demand for housing with shrinking productivity, environmental concerns, and a shortage of skilled labor. These factors have driven Japanese companies to pioneer innovative solutions—particularly in the fields of prefabricated housing, lean construction, and industrialized building systems.

Japanese homebuilders and manufacturers have responded by developing highly efficient, factory-based production systems that enable faster construction with greater quality control and less waste. The integration of modular design, automated manufacturing technologies, and total quality management principles has transformed housing delivery in Japan into a model of precision, speed, and sustainability. Many of the country’s largest builders now operate fully integrated housing supply chains, from materials procurement through to delivery and on-site assembly.

The influence of kaizen culture and the Toyota Production System (TPS) can be seen in many aspects of Japan’s housing industry—from production scheduling and just-in-time delivery to standard work and continuous improvement routines on factory floors. These lean practices have enabled Japanese builders to maintain high levels of efficiency and product consistency, even in a market characterized by customization and seismic safety requirements.

Over the past decade, Shinka Management has worked with a number of Japan’s leading housing manufacturers and suppliers to introduce international participants to the systems and mindsets behind their success. These visits and discussions serve as powerful references for organizations seeking to implement lean building practices, increase housing productivity, and explore scalable solutions to global housing challenges.

Shinka Management Japan Study Missions

Shinka Management runs programs in Japan covering a variety of themes including the Lean Japan Tour, Lean Healthcare Tour, and the Japan Housing Mission. View a video from one of our previous lean manufacturing-themed study missions to Japan.

Want to see more? Access other kaizen study trip videos via our YouTube Channel or view our latest photos on LinkedIn and Instagram.

Industry Briefing | Event Report

The Industry Briefing: Insights from Japan’s Prefabrication and Modular Construction Models brought together leading voices from academia, government, and industry to explore how lessons from Japan’s prefabricated housing sector could help reshape global industry’s approach to building.

Read the event report and access the presentation recordings here.

Inquiries

Interested in joining us in Japan for the Japan Housing Mission? To request program brochure, mission itinerary and host organization names, please fill in the form provided or email our team at

Japan Housing Mission FAQs

The following FAQ section is specific to our Japan housing industry study tour programs.

For general questions relating to our Japan study trips, including inquiries related to booking, travel arrangements and pre-departure preparation, see the FAQ section at the bottom of the Lean Japan Tour page.

What is the Japan Housing Mission?

The Japan Housing Mission is an immersive, one-week housing industry study tour in Japan designed for global professionals seeking insight into lean construction, modular building, and prefabricated housing practices. The program features factory site visits, executive seminars, industry networking and cultural experiences, offering a rare opportunity to observe Japanese building innovation and world-class manufacturing management in action.

Who should attend this program?

This study tour program is ideal for:

- Homebuilders and construction executives

- Modular and prefabricated housing specialists

- Building product manufacturers and suppliers

- Government housing departments and urban planners

- Developers, project managers, and housing investors

- Operations and supply chain professionals focused on housing productivity improvement

When will the next Japan Housing Mission be held?

The Japan Housing Mission is currently run on an annual basis. Dates for the next mission, as well as dates for all Japan-based study tour programs, can be found on the Shinka Management events calendar.

Where does the study tour begin and end?

The mission typically begins and concludes in Tokyo, Japan. Specific details, including the designated hotel and any intercity travel, will be confirmed closer to the tour start. In some cases, the program may end in a different city depending on the final site visit itinerary.

What does the program fee include?

The fee of USD $6,750 includes:

- Hotel accommodation throughout the tour

- Domestic transport within Japan

- Entry to all scheduled factory and site visits

- Seminars on Japanese management practices including lean manufacturing and kaizen

- Interpreting services and cultural support

- Group meals (excluding two free evenings and Saturday lunch)

Please note: international airfares, travel insurance and airport transfers are not included.

How many participants are expected on the mission?

Participation is capped at 20 participants to ensure quality interaction and site access. Our typical lean construction study tour group includes 10 – 20 professionals from around the world, representing a diverse mix of sectors within the housing and construction ecosystem.

What language is the program conducted in?

All seminars and tour activities are conducted in English. Our bilingual consultants provide full interpretation during Japanese-language factory tours and meetings to ensure you gain maximum value from every engagement.

Do I need experience in lean or modular construction to benefit from the program?

No. The program is structured to support both newcomers and experienced professionals. We will provide introductory seminars on kaizen and lean practices applied to manufacturing and construction to aid participants in gaining the most from factory and site visits. Similarly, there will be ample opportunity throughout the week to understand and witness Japan’s approach to prefabricated housing systems.

Will there be an opportunity to network with Japanese housing industry representatives?

Yes. In addition to meeting with management and company representatives during site visits, we also include seminars and specific networking events with representives from industry and housing-related associations.

How do I register or request more information?

Simply fill out the expression of interest form on this page, or contact the Shinka Management team directly. You’ll receive the latest Japan Housing Mission brochure, along with updates on confirmed dates, availability and registration instructions. Early inquiries are encouraged, as places are limited.

Contact Shinka Management via the contact form on this page for further information, including a brochure, itinerary, program fee details, and names of companies and factories to be visited during the week. Our team can also be emailed directly at

Our Building Industry Clients