Lean Leadership Master Class | Lean Training | Christchurch, New Zealand

The Lean Leadership Master Class is designed for those interested in fostering a culture of continuous improvement within their organization. This lean training course is led by Hyodo Sensei, former factory manager and director of the Toyota HiAce factory in Japan.

Date: 24 Feb 2020 - 25 Feb 2020

Time: 8:30 am - 4:00 pm | Timezone: Pacific/Auckland

Training Location: TBC, Christchurch, New Zealand

Site Location: Spunlite Poles, 611 Halswell Junction Road, Hornby South, Christchurch, 8042, New Zealand

Pricing: AUD 1,295

No GST charged for New Zealand-based training courses

For further details of Shinka Management’s training programs, see our lean training page or contact us.

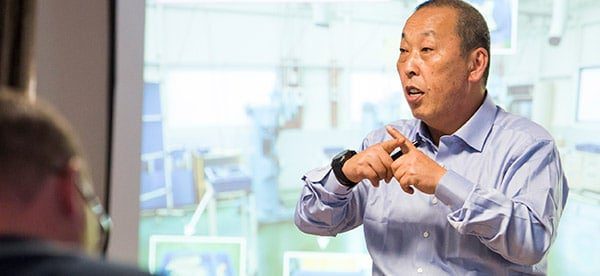

Hyodo Sensei

The master class will be led by Akinori Hyodo, a long-time Toyota Production System leader and former factory manager at the Toyota factory in Japan responsible for the manufacture of the Toyota HiAce vehicle. Now retired as a factory manager, Hyodo Sensei is a Senior Consultant with Shinka Management supporting our clients with lean consulting, lean training and the Lean Japan Tour.

Career highlights include:

- Factory Manager Toyota Parts Factory

- Factory Manager at Toyota Assembly Plant

- 13 year member of All-Toyota Kaizen Promotion Team

- 27 years leading TPS at No.1 quality ranked Toyota factory

- Consulting globally serving a wide range of industries

Who is this for?

This master class is designed for senior managers and lean practitioners interested in fostering a culture of continuous improvement within their organisation. You will learn first-hand about how process improvement is achieved within Japan’s leading companies, and more importantly, how to implement these practices within your operations.

Particularly relevant sectors include manufacturing, food and beverage, mining, wholesale & retail trade, logistics and transport.

Topics Covered

This two-day lean leadership training will focus on the application of lean principles and the Toyota Production System (TPS) to sectors outside of automotive. The course will go beyond theory to discuss how lean thinking can be implemented and sustained within a company.

- TPS principles

- Developing human assets

- Role of top management

- Factory visit and diagnosis

- Factory visit review

- 5S and visual management

- Standardized work creation

- Continuous improvement culture

The course will also include an overview of the operations at the Toyota HiAce factory in Japan, as well as an afternoon tour and mini diagnosis at Spunlite Poles. This training is presented in partnership with Simply Lean Business Solutions.

What our lean training participants have said…

The training was great. Provides clarity and a practical approach to what can seem a very complex process.

read more

Thank you Shinka Team – this is very useful and, believe me, we will use it extensively. Rest assured that we will call you whenever something is required as the team is extremely satisfied with your time with us and, in particular, I have learnt a lot of new things and you’ve made me think…

read more

QTEC Fire Services partnered with Shinka Management to implement the 5S system within its operations at its head office in Brisbane. We are confident that the new knowledge and information we received during the three days in-house training will further help to make the company even more efficient and understand this is only the first…

read more

The training was intense but had great value because the subjects have been explained in such a clear manner opposite to some European experts who know how to turn lean into some NASA scientific miracle from another planet.

read more

The Shinka Team enables an excellent learning environment for lean practitioners at all levels. They possess excellent communication skills and facilitate learning events incorporating theory, discussion and practical exercises. I would recommend to anyone interested in improving their business.

read more

Register today

One of our team will follow up to confirm details and to provide an invoice.