6-month Program with Toyota Lean Expert

In a first for New South Wales industry, your company has the opportunity to experience a kaizen improvement journey with one of the world’s leading authorities in lean manufacturing.

Shinka Management is excited to bring Akinori Hyodo, a veteran of the Toyota Production System (TPS), to Sydney and regional NSW to share experience and know-how developed over a 40-year career within Toyota in Japan.

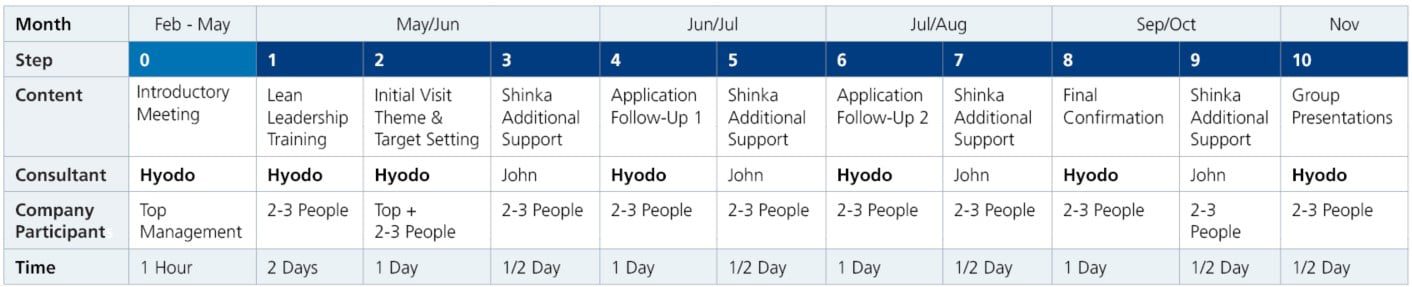

Over the course of six months, Hyodo Sensei, supported by Australian lean manufacturing consulting firm Shinka Management, will help your company develop its lean leadership capability whilst guiding you through an improvement implementation project specific to your operations. Participating companies will benefit from an initial two-day master class on lean fundamentals, twice-monthly on-site support, as well as sharing of learnings and outcomes with other participating companies.

Program Overview

Training Component

The program commences in May 2022 with a shared training event. Up to three participants from your company will be introduced to the fundamental thinking required for a leader within a lean manufacturing organisation. The two-day program will provide them with a genuine understanding of TPS enabling them to implement and sustain a kaizen culture.

On-Site Implementation Support

Over the length of the program Hyodo-sensei will spend four days supporting your company on-site with setting the direction, focus and target for your kaizen activity – and coaching you through a full cycle of improvement. Between visits by Hyodo-sensei, Shinka Management senior consultant John Thomas will work with you to provide support and advice in keeping efforts on track to achieve your kaizen target.

Developing People

A key objective of TPS is to develop people. This program will touch all levels of your company – from top management to operator level. The employees you select to be the participants of the initial training will take part in a unique journey of insight and discovery never previously available in Australia.

Learning from Others

The program encourages your company to share your kaizen journey with up to four other participating companies within the same learning group. This culminates with a presentation event in November to share and celebrate your successes.

Location

Group Training Location:

TBC based on participating companies

Follow-up Coaching Location: Your on-site location

Schedule

Run over 6 months: May to October 2022

1 x Training for up to 3 employees

4 x One-day sessions with Hyodo

4 x Follow-up sessions with Shinka Management senior consultant

Report presentation event: November 2022

Program Cost

Fee:

$ 18,750 (after funding applied)

$ 37,500 full fee

Funding:

50% Government + 50% Industry (eligibility criteria applies)

Program Delivery

The program will be delivered by Adelaide-based lean management consultancy Shinka Management, a specialist in supporting Australian and global industry through the transfer of Japanese lean management know-how.

Akinori Hyodo Career Highlights

- Factory Manager & Director, Toyota HiAce final assembly plant

- 14 years deploying the Toyota Production System (TPS) across multiple final assembly plants

- 10 years training and consulting internationally in lean manufacturing

All COVID precautions will be taken to ensure a safe program.

For further information and to discuss your participation on the project please contact us, or to register to participate, please complete the form below.

Register your intention to participate in the Kaizen Accelerator Program

Following receipt of your details a representative of the