Rethinking Homebuilding: Transforming Housing Construction through Manufacturing Principles

Can you imagine buying a car that was built on a factory shopfloor covered in waste — piles of metal offcuts, discarded parts, and materials tossed aside because they didn’t quite fit? Most of us would walk away instantly.

Yet homes, one of the most significant purchases people make in their lifetime, are often built in environments where waste and inefficiency are simply accepted as part of the process. This raises an uncomfortable question: why do we tolerate waste and inefficiencies in housing construction that we would never accept in car manufacturing?

The answer to this question challenges us to rethink how homes are built and to examine what lessons from advanced manufacturing could be applied to the housing construction industry.

Waste and Inefficiencies in Traditional Housing Construction

Before exploring what we can learn from the manufacturing sector, it’s important to understand the specific challenges embedded in traditional housing construction practices.

Traditional homebuilding faces a wide range of issues that make it inherently less efficient and more prone to generating waste than modern manufacturing. These factors accumulate over the course of a project, creating complexity, unreliability and significant management difficulties. The following points outline some of the key issues that contribute to these challenges:

- Uncontrolled work environments: Housing construction takes place on open, variable sites exposed to weather conditions and other external factors that disrupt schedules and reduce productivity.

- Lack of standardization: Each home tends to be treated as a one‑off project, often leading to inefficient building practices and approaches on construction sites.

- On‑site cutting and adjustments: Materials are frequently cut, trimmed, and modified on-site, creating offcuts and waste that would be unacceptable in a controlled factory setting.

- Inconsistent supervision and labor variability: Fluctuating availability of skilled workers and inconsistent oversight often result in uneven quality and delays.

- Fragmented subcontractor involvement: Heavy reliance on multiple subcontractors can lead to miscommunication, inconsistent workmanship, and duplicated effort.

- Supply‑chain disruptions: Late or out‑of‑sequence deliveries interrupt workflow and force builders to delay work or improvise, which can lead to the risk of errors and rework.

- Missed deadlines and cost blowouts: Inefficiencies such as rework, material waste, labor inconsistencies, and supply‑chain delays frequently push projects behind schedule and over budget, making it difficult for builders to deliver homes on time or maintain financial viability.

These challenges highlight the significant gap between traditional housing construction and the precision, consistency, and waste‑minimizing practices that define advanced manufacturing environments. They reveal an industry still heavily dependent on variable site conditions, manual adjustments, and fragmented workflows. Recognising these limitations is essential to rethinking how we approach homebuilding.

This is where the experience of the Japanese housing industry becomes particularly valuable, as Japan has spent decades developing manufacturing‑inspired approaches to address and overcome these inefficiencies in the housing construction sector.

How the Japanese Housing Industry Responded to These Challenges

Japan’s housing industry has long confronted the inefficiencies and waste inherent in traditional on‑site construction. Instead of accepting these issues as unavoidable, leading Japanese builders have applied principles rooted in lean manufacturing, many of which were pioneered in Japan’s automotive sector.

To address the limitations of building homes on unpredictable construction sites, the industry gradually shifted towards factory‑based production, including highly standardized components, modular construction, and unitized building systems. By moving much of the work into controlled factory environments, Japanese housing companies have achieved levels of precision, efficiency, and quality control that are difficult to replicate on traditional building sites.

This transformation has allowed Japanese housing construction companies to:

- Reduce material waste through precise, automated cutting and assembly

- Improve quality by standardizing components and processes

- Shorten construction timelines by manufacturing standardized components, modules and units in parallel with site preparation

- Allow workers to work more efficiently and safely under standardized processes to deliver consistent, high‑quality results

- Minimize rework and defects through rigorous factory‑based inspections

- Stabilize labor needs by relying less on fluctuating subcontractor availability

- Maintain consistent production timelines unaffected by weather or unpredictable labor allocation

- Lower overall costs through economies of scale and repeatable production systems

The result is a housing sector that operates far more like advanced manufacturing than traditional construction.

Key Learnings for the Housing and Construction Industry

Drawing on the experience of Japan’s housing industry, it becomes clear that residential construction must be viewed as a form of manufacturing in its own right. As every country has its unique regulatory environment, industry structure and market conditions, Japan’s methods cannot always be replicated easily elsewhere. However, there are still valuable learnings that can be considered and applied.

The following insights highlight principles that other housing sectors can adopt to improve efficiency, reduce waste, and enhance overall quality.

1. Reframe Housing Construction as a Manufacturing System

Seeing housing construction as manufacturing rather than a one-off craft enables greater consistency and control. Standardization and repeatability significantly reduce waste, errors and cost overruns. When homes are designed and built with a manufacturing mindset, efficiency, reliability, and quality naturally improve across the entire build.

2. Strengthen Supply‑Chain Integration

Japanese builders tightly coordinate suppliers, ensuring materials arrive in the correct sequence and in the right quantities. This reduces delays, rework, and cost blowouts.

3. Move Work Off‑Site and into Controlled Environments

Factory production eliminates many of the variables that disrupt on‑site construction — bad weather conditions, labor inconsistency, and supply‑chain timing issues. Controlled environments enable precision and predictability.

4. Adopt Modular and Unitized Systems to Improve Speed and Quality

Modular construction allows large portions of a home to be built simultaneously, reducing overall build time and improving quality through factory‑based subassembly.

5. Build a Culture of Continuous Improvement

Japanese companies embed Kaizen — continuous improvement — into their operations, constantly refining processes to reduce waste, improve quality, and enhance customer satisfaction. The housing construction sector can adopt the same lean mindset by consistently strengthening its work practices and processes, drawing on effective examples from the manufacturing sector.

Closing Thoughts

In Australia, where I currently live, the housing crisis has become one of the most urgent challenges facing the country. But this challenge is far from unique. Across many advanced economies — including the United Kingdom, Canada, the United States, New Zealand, Ireland, and parts of Europe such as Germany and the Netherlands — governments and industry are grappling with the same core problem: housing demand continues to outpace supply, pushing affordability further out of reach for households.

In response, policymakers, financiers, and industry bodies in many of these countries are now working more closely together to identify practical ways to accelerate housing delivery. In Australia, one particularly encouraging development has emerged from the banking sector. From 2025, major lenders have begun lifting long-standing restrictions on financing modular and prefabricated homes within their lending policies. This shift removes a significant structural barrier that has historically slowed the adoption of off-site construction, and it mirrors a growing international recognition that conventional building approaches alone are no longer sufficient to meet housing demand.

With similar pressures being felt globally, the lessons from Japan are especially relevant. Japan has demonstrated, over decades, that housing can be delivered at scale, with consistent quality and cost control, by applying manufacturing discipline to residential construction. As supportive policy and financial conditions begin to align in Australia and other housing-constrained countries, the opportunity now exists to rethink how homes are designed, produced, and delivered.

Adopting the efficiency, standardization, and continuous improvement mindset found in modern car production and lean manufacturing is not without challenges — including market perception, regulatory frameworks, and industry capability. However, where these barriers are addressed deliberately, housing systems can reduce waste, improve build quality, and deliver better homes faster. The path forward is clear: build smarter, waste less, and treat housing as the manufacturing process it truly is.

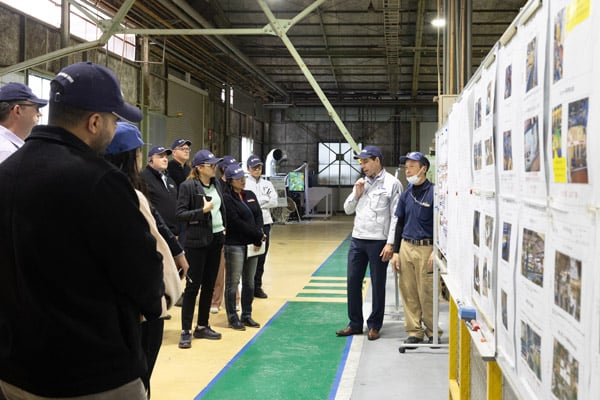

Eri Dennis is General Manager – Japan Programs at Shinka Management, a lean training and consulting firm with clients in over 70 countries. Eri is a regular leader of Shinka Management’s Japan study tour programs, including an annual Japan Housing Mission, which provides industry leaders with direct exposure to Japan’s highly industrialized housing sector through site visits, expert briefings, and hands-on learning focused on lean production, prefabrication, and housing supply innovation.

Japan Housing Mission

Shinka Management’s Japan Housing Mission is a focused study program offering industry leaders direct insight into how Japan delivers high-quality housing at scale. Through factory and site visits, expert briefings, and guided discussion, participants explore Japan’s industrialized housing systems and the application of lean principles and integrated supply chains.